Products and Services

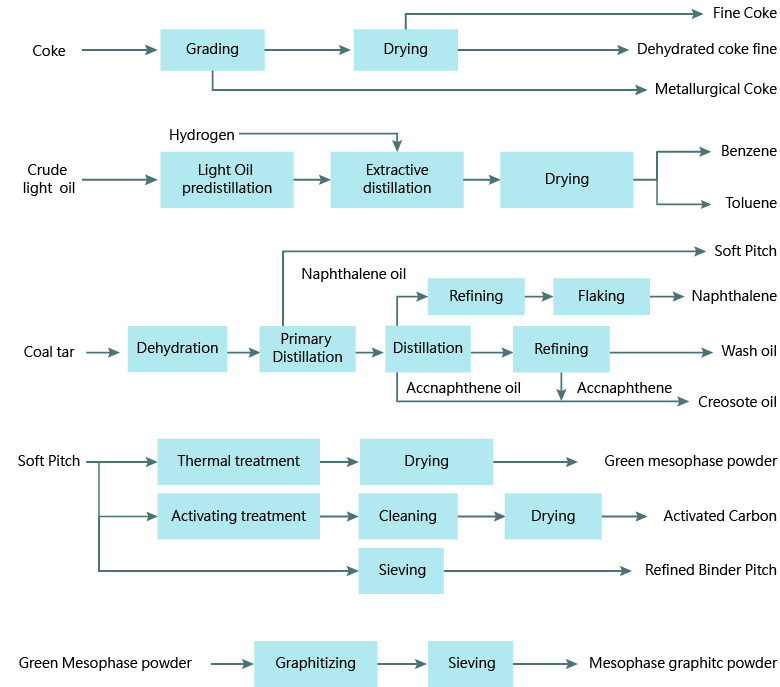

We acquire over 90% of our raw materials from China Steel Corporation and Dragon Steel Corporation under CSC Group. Specifically, raw materials from China Steel Corporation are transported by pipeline as this mode of transportation can reduce carbon emissions from transportation by vehicle. The production process for major products and raw material management at CSCC are detailed as follows:

Production process for major products

Raw material management

Acquisition method

China Steel Corporation - by pipeline

Dragon Steel Corporation - by tank truck

light oil

Acquisition method

China Steel Corporation - by pipeline

Dragon Steel Corporation - by tank truck

Import from abroad by sea freight

Acquisition method

China Steel Express Corporation

SASB: Description of the Chapter of Sustainable Products

Under the trend of global carbon reduction issues, countries are taking renewable energy as the main driver for future development. The demand for batteries and energy storage devices has emerged along with the trend. CSCC processes soft pitch to produce high-value lithium-ion battery anode materials, advanced carbon materials, isotropic graphite and other diversified fine carbon products to facilitate CSCC to enter the green industry and continue to develop innovative and sustainable products to create green value.

Amid evolving industry trends, there is significant emphasis on the durability, efficiency, and safety of batteries. The Company produces high-end, long-cycle life, and high charge-discharge rate mesophase graphite carbon microspheres, which are critical anode materials for power batteries used in electric power tools, electric buses, and energy storage systems. Additionally, with the global push towards green energy development, wind power generation is expected to experience substantial growth. Supercapacitors, as essential components, will become a focal point in the market. Our advanced carbon materials serve as key raw materials for high-capacity, long-life supercapacitors, positioning our products as pivotal elements in this emerging trend.

In alignment with the expansion plans of domestic and international clients, the Company is actively enhancing its presence in the global market and has initiated production line expansion projects. We are continually refining and improving the quality and value of our carbon materials brand, striving to create economic benefits by enhancing product efficiency for end users. Additionally, we are strengthening our connections with customers and increasing service satisfaction.

Sales and percentage of sustainable products in the last three years:

In 2024, our carbon materials production plant utilized 915,000 kWh of renewable energy through a renewable energy purchase agreement, primarily sourced from direct solar power supply from rooftop photovoltaic installations. Through a Power Purchase Agreement (PPA), we procured green electricity and obtained a total of 915 Taiwan Renewable Energy Certificates (T-REC), with each certificate representing 1,000 kWh. According to the Energy Bureau's notification, our required compliance for 2024 was 543 kW, and we exceeded this obligation by achieving 732 kW, surpassing regulatory requirements. The T-REC certificate numbers are as follows: 23SP0057-B024000001~532, 23SP0058-B024000001~378, 23SP0042-B024000081, 23SP0042-B024000121, 23SP0042-B024000219, 23SP0042-B024000325, and 23SP0042-B024000431.