Fine Carbon Materials

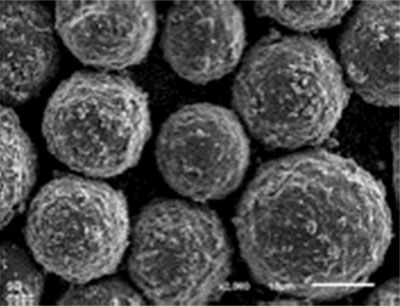

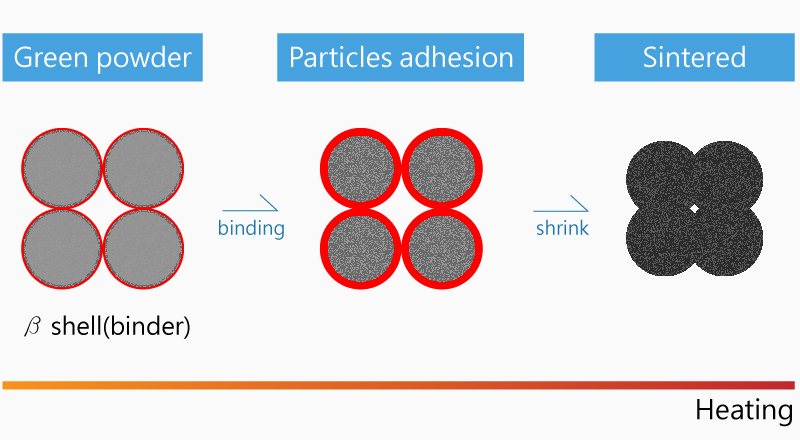

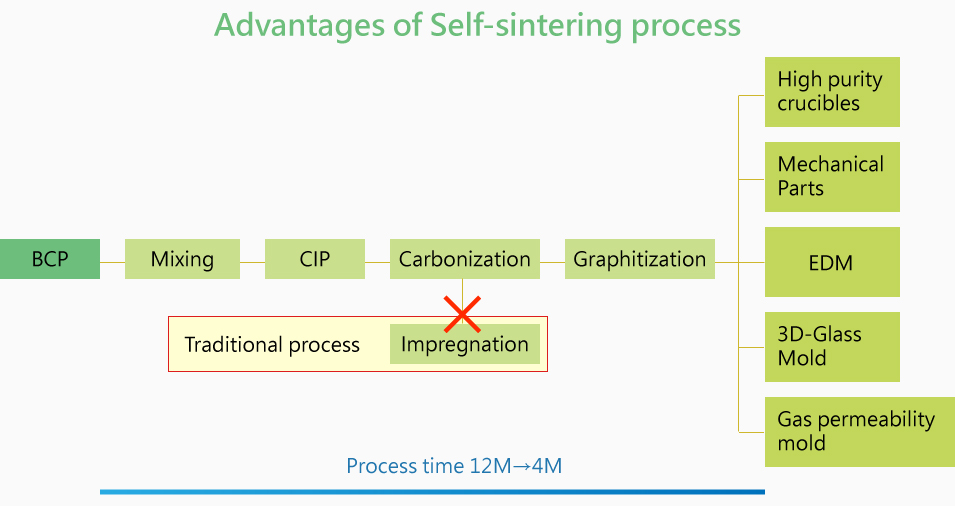

CSCC's isotropic graphite uses self-produced Meso-phase carbon powder(MCMB) as a raw material. Due to the self-sintering characteristics of MCMB, isotropic graphite can be produced without impregnation process, which saves time and is environment friendly. Compared with commercial products, our products have the properties of high density, high mechanical strength and high purity.

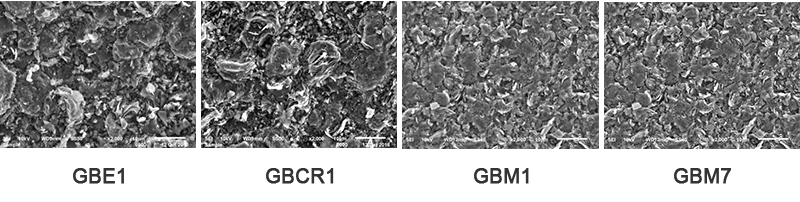

| Specification of GB Series | |||||

| ITEM | Unit | GBE1 | GBCR1 | GBM1 | GBM7 |

|---|---|---|---|---|---|

| Density | g/cm3 | 1.88 | 1.85 | 1.95 | 1.91 |

| Bending Strength | MPa | 56 | 45 | 64 | 46 |

| Compression strength | MPa | 110 | 100 | 142 | 108 |

| Coefficient of thermal expansion | 10-6/K | 5.4 | 5.1 | 6.2 | 5.9 |

| Hardness Shore | - | 63 | 65 | 76 | 76 |

| Particle size | μm | 10 | 10 | 4 | 4 |

| Thermal conductivity | W/mK | 130 | 110 | 81 | 70 |

| Ash content | ppm | 200 | 70 | 200 | 200 |

| Max. Size | mm | 300*300*100 φ200*H300 | φ300*H350 | 230*150*70 | 300*300*100 φ200*H300 |

| Characteristic | High permeability, High thermal conductivity | High purity, High thermal conductivity | High Density, Ultrafine particles | Ultrafine particles, good machinability | |